WELDING PIPE EUQIPMENTS

You are hear : Home > Products > Welding Pipe Equipments

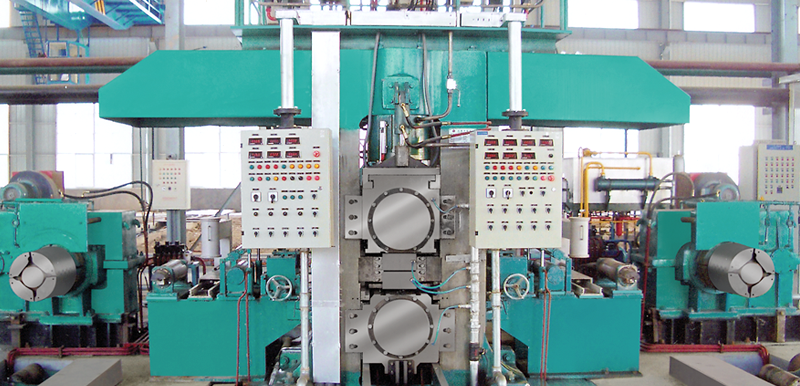

Four-high reversing cold roll mill

Suitable for mild steel, stainless steel, and special steel.

Transmission method: working rollers transmission and supporting rollers transmission. Control methods: common electric pressing down and hydraulic pressing down through AGC system.

Transmission method: working rollers transmission and supporting rollers transmission. Control methods: common electric pressing down and hydraulic pressing down through AGC system.

MAIN TECHNICAL PERFORMANCE

| 650 rolling machine | 750 rolling machine | 900 rolling machine | |||||||||||

| Φ200 Φ600X650 |

Φ165 Φ450X450 |

Φ220 Φ450X450 |

Φ175 Φ450X450 |

Φ2305 Φ450X450 |

Φ180 Φ450X450 |

||||||||

| Black thickness | 2.0~4.0 | 1.0~2.5 | 2.0~4.0 | 1.5~3.0 | 2.0~2.75 | 1.0~2.75 | |||||||

| Product thickness | 0.3~1.5 | 0.2~0.6 | 0.5~1.0 | 0.3~0.6 | 0.4~1.0 | 0.3~0.6 | |||||||

| Strip with | 450~580 | 450~580 | 550~680 | 550~680 | 600~800 | 600~800 | |||||||

| Transmission | Working roll | Working roll | Working roll | Working roll | Working roll | Working roll | |||||||

| Rolling pressure | 6000 | 6000 | 7000 | 7000 | 8000 | 8000 | |||||||

| Pressdown method | electric | hydraulic | electric | hydraulic | electric | hydraulic | electric | hydraulic | electric | hydraulic | electric | hydraulic | |

| Speed(m/s) | 1~3 | 4~6 | 1.5~4 | 4~8 | 1~3 | 4~6 | 1.5~4 | 4~8 | 1~3 | 4~6 | 1.5~4 | 4~8 | |

FUNCTIONS & CHARACTERISTICS

1. Suitable for mild steel, stainless steel, and special steel.

2. Transmission method: working rollers transmission and supporting rollers transmission. Control methods: common electric pressing down and hydraulic pressing down through AGC system.

3. Equipped with hydraulic bending working rollers which can fast adjust the gibbous degree of rollers to change the distribution of touching pressure between rollers in order to control the plate form.

4. With simple construction, easily maintenance,and less investment.

5. It is equipped with AGC system to get high precision,which is especially suitable for rolling high precision requirements of cold rolled strips.

Components

Entry tension reel(unloading car) → front device → four-high rolling mill → rear device → exit tension reel(unloading car)etc.Uncoiler and head straightening machine could be equipped as per user’s needs.